June 22, 2021

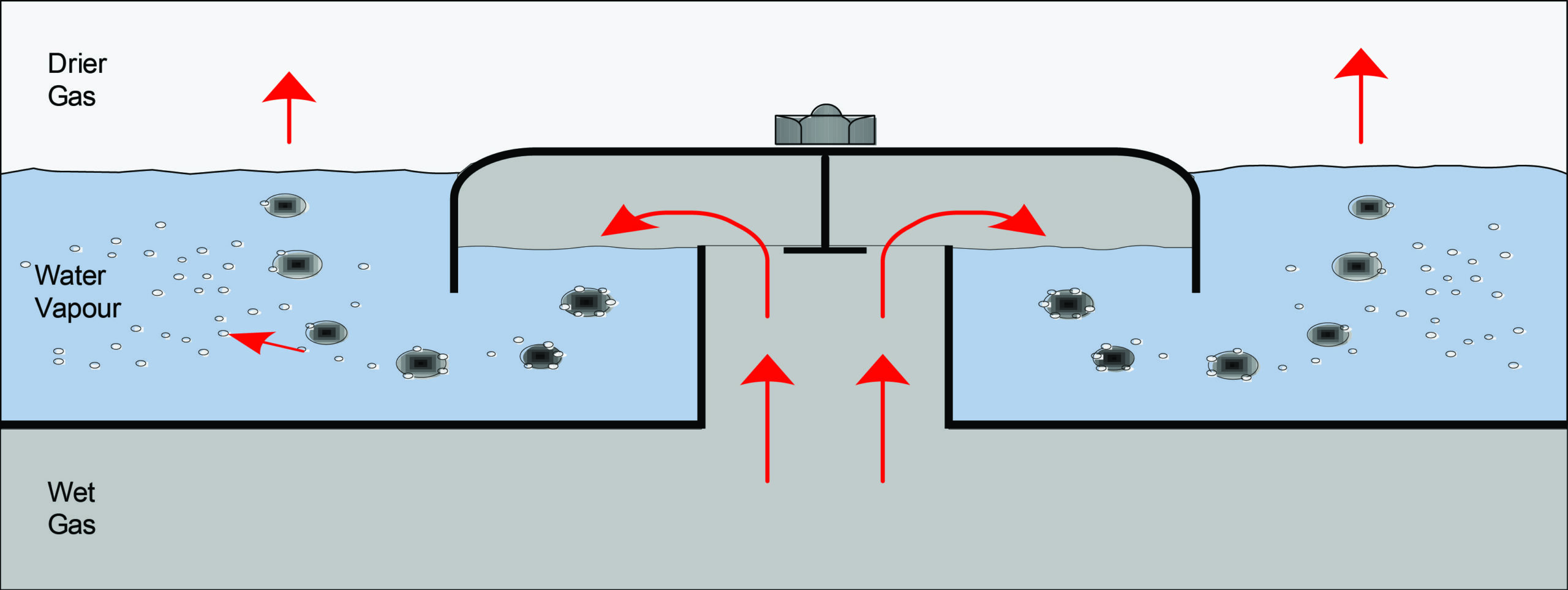

Glycol dehydration is a common method utilized in the oil & gas industry to remove water from Natural Gas. Natural Gas is passed through a contactor with a counter-flow of triethylene glycol where the glycol absorbs the water from the gas. The glycol then goes through a regeneration process to remove the water which allows it to be reused. The regeneration process includes the use of a reboiler and stripping gas to optimize the purity of glycol.

It is important for water to be removed from natural gas as the presence of water could lead to the formation of hydrates, ice-like substances that could block pipelines, and acid gases, which promote corrosion.

Understanding the principles and operations behind a glycol dehydration plant can be intimidating as mistakes on-site can lead to expensive and dangerous consequences. The training that ESD offers, provides comprehensive and easy-to-follow classroom instruction that integrates hands-on experience through dynamic simulation models. These simulation models allow for the risk-free application of concepts surrounding glycol dehydration so that delegates can be confident in their understanding of both the theoretical and practical aspects of the process.

Currently, we at ESD are working on an updated glycol dehydration and regeneration simulation model that is a feature of our “Principles of Glycol Dehydration” two-day course. This updated model, which is designed to replicate the real-life process, will make the simulation more user-friendly and realistic.

Our summer Engineering and IT Co-Op students are heavily involved in the process of creating this new model. They have been been able to expand on the concepts learnt in their university coursework, while also developing some new technical skills. We hope that you learn as much as they have in this course!