After years of deliberation, your company finally decided to invest in Carbon Capture and Storage (CCS), but now construction has started, and it’s just a matter of time before it’s time to commission. Soon your equipment, processes, and people will be put to the test. You’ve taken the right steps to mitigate your technical risk—but have you done everything you can to make sure your people are equipped to operate your new plant?

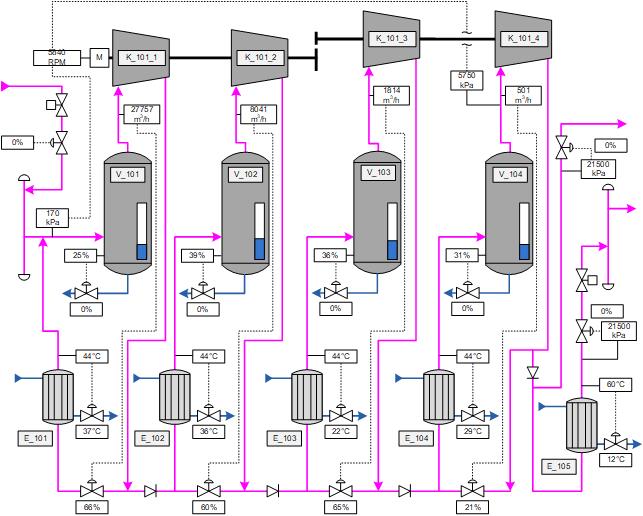

Handling carbon dioxide (CO2) is more complicated than you might imagine. CCS plants usually operate with CO2 in a dense or supercritical state, which means your operators will be dealing with high-powered compression, aggressive corrosion, extreme cooling upon expansion, and other peculiarities that they haven’t seen before.

How can you prepare?

ESD Simulation offers courses that use state of the art simulation models to train operators how to commission, start up, shut down, and operate your new process equipment. It’s practical hands-on training you simply can’t get anywhere else.

What will they learn, exactly?

Your operators won’t just get a primer on CO2; they’ll develop an intuition for how the gas behaves when wet or at high pressures. They won’t just get a process overview; sure, they’ll learn about the importance of each unit and how compression fits into the whole system, but they’ll also get into the weeds: how can anti-surge control for centrifugal compressors be applied to a multi-stage compression system, and how does dense phase CO2 affect control valves and instrumentation?

You should want your operators to understand the cause-and-effects and the critical process loops. You should want them to be able to describe how to start up and shut down the entire process by memory, and to quickly identify safety elements and key hazards

Reach out to ESD to arrange training, and empower your team with the skills they need to capture the CO2 you set out to capture.